No matter where you look on an old horse drawn wagon or western vehicle, you're likely to see some type of metal attached nearby. While each piece of iron and steel can have different - and even multiple purposes - the most common function of many forged and hardened parts is that of protection... Protection against excessive wear and tear as well as a safeguard against unnecessary wood stress and fatigue. Ultimately, this 'body armor' was engineered to deliver greater durability and less maintenance issues.

These and other technologies inside an old wooden vehicle are just part of the intrigue any early set of wheels can hold. With that in mind, below are a few typical areas of protection as they were addressed by numerous wagon builders. If you look close at virtually any 19th or early 20th century piece, you can often see even more areas where the maker placed fortifications.

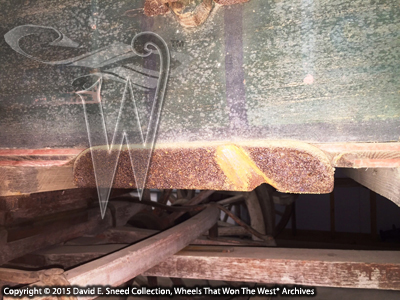

Rub irons - These are the cast metal (and sometimes angle iron) pieces bolted or riveted to the lower box sides behind the front wheels. The primary purpose of these metal plates was to protect the box from damage when the wheels turned too tight. Every rub iron was expected to eventually wear out. As a result, they were designed to be easily removed, reused, and replaced.

Tongue irons - The tongue could receive considerable damage from numerous sources including repetitive rubbing, chipping, and gouging from the action of the doubletree, singletrees, draft animals, and fifth chains. As a result, it's not uncommon to see extensive ironing applied to appropriate areas on the tongue.

Box chafe irons - These flat metal plates were sandwiched between the bolster stakes and the box sides to help prevent undue chafing on the box by the standards.

Not all wagon makers used chafe irons on the box but many builders did include a myriad of similar quality details throughout the designs.

Box top irons - The thinner top edges (and sometimes the ends) of a wagon's sideboards and end gates were often fitted with these narrow metal strips. The objective was to reduce or eliminate unnecessary board fractures and wear as materials were loaded, unloaded, and positioned on top of the boards.

Reach boxes - Fitted between the rear axle and bolster, many makers utilized a rectangular frame of either cast iron or fabricated sheet iron around the reach. The purpose was to help prevent the reach from wearing against the axle and bolster.

By covering the tops of sideboards and end gates with metal strips, wagon boxes were protected from unnecessary damage during normal use.

Reach boxes were designed to help preserve the structural integrity of the reach, rear bolster, and rear axle in a wagon gear.

Encased hubs - Wooden hubs encased in metal were a common practice in the 19th and early 20th centuries. While only a few farm wagon builders are known to have used similar designs, there were numerous manufacturers of lighter vehicles that employed metal clad wooden hubs.

Clouts - Prior to, and sometimes after, the invention of the thimble skein, the ends of wagon axles were fitted with 'clouts.' These metal plates were attached to the top and bottom of each axle end to provide easier draft while also protecting the wooden axle from excessive wear.

Sand board and bolster plates - These pieces were engineered to take a significant amount of punishment and were typically thicker than most other metal on a wagon. They were configured in a variety of ways. Some were heavy flat bars while others had a cup and saucer design. Still others looked more like a fifth wheel, offering greater protection for the king bolt.

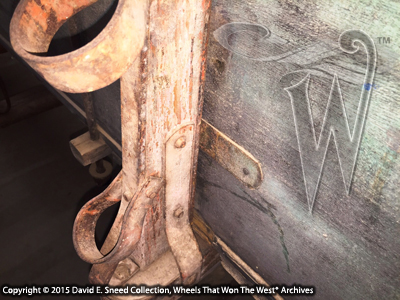

Sway bar, reach, & slider irons - In many dead axle wagons, there are multiple parts of the front hound that are designed to move back and forth over or under the reach as the front wheels turn. Portions of wooden pieces in these areas are typically plated with metal to help preserve the structural integrity of the reach and hound sections.

The forward hounds of a wagon were often clad with metal strips as shown above. This extra 'ironing' helped guard against excessive wear and tear on the wood.

Reach plates - Some reach plates are designed with additional iron framework to prevent the rear hounds from rubbing and wearing against the reach.

As I mentioned in the opening to this blog, there are numerous other areas of early western vehicles that received "ironing" to protect, strengthen, and underscore the quality of a particular piece. Clearly, the blacksmith shops had plenty to keep them busy in the production and repair of these vehicles. From the mountains, rivers, and plains to the deserts, valleys, forests, and fields, period western transports needed protection. In fact, from the time they left the shop of a specific maker, these heavier wheels were regularly subjected to torturous terrain, burdensome cargo, and extensive exposure to the raw elements of the outdoors. By the very nature of their functions, they were expected to take a beating and keep rolling with minimal maintenance. It was a tall order and many did it surprisingly well.

Please Note: As with each of our blog writings, all imagery and text is copyrighted with All Rights Reserved. The material may not be broadcast, published, rewritten, or redistributed without prior written permission from David E. Sneed, Wheels That Won The West® Archives.

Please Note: As with each of our blog writings, all imagery and text is copyrighted with All Rights Reserved. The material may not be broadcast, published, rewritten, or redistributed without prior written permission from David E. Sneed, Wheels That Won The West® Archives.