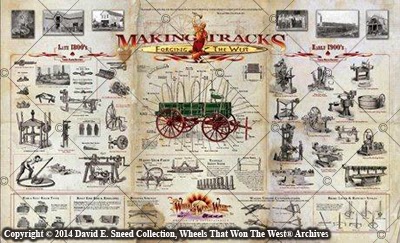

Cross sills, sideboard cleats, straddlerstaples, running boards, sliders, sway bars, bunters, fifth chains, standards,circle irons, brake shoes, reach boxes, box straps, boot ends, bolster ironextensions, box tighteners, rub irons, sand board plates… The list can go on and on. Clearly, there are a lot oftechnical-sounding terms used when referencing wagons, coaches, and otherwestern vehicles. Beyond the obviousadvantages in allowing easier communication with others, understanding thesedesignations is the first step to gaining real insight into the purposes of thedesigns themselves. To help growknowledge of many of these near-forgotten terms, a few years ago, we created afirst-of-its-kind illustration of wagon parts and made it the centerpiece ofour Making Tracks limited editionprint.

For the sake of discussion here, we’llcover just a few of the designations mentioned above. ‘Cross sills’ on a wagon refer to thehardwood supports attached beneath the box floor. Positioned transverse to the box length, themore cross sills a wagon has can be one indicator of the original expense ofthe vehicle. Beyond the added cost ofthe material and time to install it, wagon boxes with more cross sills wereoften more desirable because they tended to be more stable and solid – allthings being equal with other box designs. The old adage, “You get what you pay for,” was just as true a centuryago as it is today.

‘Box tighteners’ are typically placedover or mounted onto the sideboards of a farm wagon. To get a clearer picture of these devices, weneed to understand their purpose. Firstand foremost, they are engineered to help pull the sideboards tight to eachother. The intent is to seal any gapsbetween the sideboards, thereby helping prevent the loss of smaller grain andseed. There are a variety of differentdesigns that do this. Some also work tohelp eliminate gaps between the lowermost sideboard and the floor while alsostiffening the sides of the box. Often,these ‘tighteners’ were used in conjunction with metal flashing between theboards to help further prevent spillage.

Some time back, I received a questionabout rub irons. On a wagon, these arethe metal bars or plates positioned behind both front wheels on the lowermostsides of the box/bed. They can be shapeda number of different ways for different reasons, but their primary purpose isto shield the box from damage caused by a wheel turned too tight. Beyond their protective purpose, many aren’taware that each iron is built to be able to be used twice. In other words, when the abrasion from awheel’s metal tire eventually cuts through the iron, leaving it too worn foreffective use, the piece is designed to be unbolted, turned around, andswitched to the other side of the wagon box. This is an important distinction I’ve seen misinterpreted numeroustimes.

At the end of the day, the best advicefor any involved subject is… Don’t be afraid to ask questions. We all have to learn sometime. Getting to know proper vehicle nomenclatureand design purposes will help minimize challenges from miscommunication andgive you an even deeper appreciation for the original builders of thesevehicles.