Most modern day wheelwrights will tellyou that the complexity of wooden wheels can be deceiving. I mean, they look simple enough – just somepre-cut, shaped, and measured wood fitted together and bound up with steel bands. Can’t be that much to it, right? Wrong. The subject is so deep that 19th and early 20th century practitionershad multiple, regularly-issued publications devoted to covering the continual challenges,designs, and intricacies of the craft.

Like other areas of a westernvehicle, an early wooden wheel can be divided into the three primary areas ofwood, paint, and metal. That’s the endof the simplicity. So, if you were hopingyou’d learn all there is to know about wooden wagon and coach wheels from this week’sblog, you’re about to be disappointed. As with so much early vehicle history, there’s too much involved in thisfield of study to treat it lightly. Thatsaid, the first step to fully appreciating any subject is to better understandits depth. So, hold on. We’re about to dive head first into anextensive and complicated trade.

|

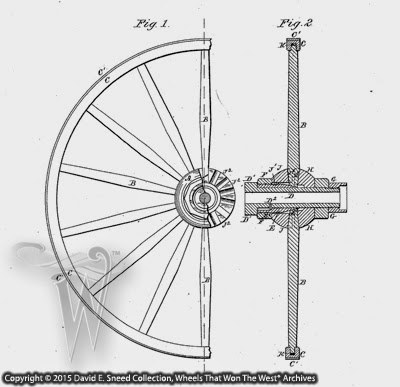

| The complexity of early wagon wheels isreinforced by numerous 19th and early 20th century patents vowing improvementson previous designs. |

Have you ever wondered why hub lengths, hubdiameters, hub bands, spoke positions, and spoke fittings are sometimesdifferent? How about the design offelloes – What dictates their size and why are some wheels engineered with bent felloes and others arecut? With cut felloes, why are there‘usually’ only two spokes per felloe? Have you ever seen a wheel with one spoke per felloe? Yes, it happened. In fact, it had several purposes and it couldbe a clue pointing to a particular maker.

Ever found yourself wondering, “What arethe advantages and disadvantages of the different styles of wheels?” Do you know the differences between Warnerhubs, Sarven hubs, Shell band hubs, Compressed band hubs, Iron Clad hubs,Archibald hubs, and regular ol’ wooden hubs. These details are important as they represent a significant part of anyearly vehicle’s personality and provenance. Clearly, there’s a lot going on beyond the surface of an old set ofwheels. Hence the popularity of periodpublications like The Blacksmith &Wheelwright, The Spokesman, The Hub, The Carriage Monthly and numerousother early books and periodicals.

|

| The Blacksmith & Wheelwright was a well-known trade magazine for U.S. vehicle builders during the late 1800’s and early 1900’s. |

Wooden wheels also need the correctpitch, gather, dish, size, fit, strength, elasticity, and resilience. In other words, while different wood types,sizes, and shapes are used in particular areas, the whole design must beproperly positioned and balanced to run free, true, strong, and durable. Reinforcing these standards, most periodbuilders boasted of how little draft was required to pull their wagon. Of course, none of this overview gets into theequally complicated topics related to the various cast and steel skein designs, rollerbearings, steel axle spindles, or other types of surfaces the wheel boxings(inner wheel casings) were fitted to.

One of the more prominent wheelwrightshops in the U.S. is Hansen Wheel &Wagon Shop in Letcher, South Dakota. According to Doug Hansen, his team will build, repair, and sell morethan 100 sets of wheels in the course of a year. From stagecoaches, cannons, carriages, andhitch wagons to farm, military, and chuck wagons, it’s a commitment thatrequires a solid understanding of the vast technology in so many woodenwheel designs.

Likewise, early builders recognized thatwheels were the literal foundation of a vehicle and, as such, were specificallyengineered to retain the right support and performance for the entire piece. That dedication to quality appeared in avariety of forms; each recognizing that no other part of a western vehicle ismore vital to the whole than the wheel. From tire andspoke rivets to bolts, dowels, bands, channels, and a seemingly endless array ofpatents, every wooden wheel is full of innovation, purpose, and expertise. It’s literally ‘the way they rolled.’

We’ll dissect the wheel in more detailin a later blog but felt this overview would be a good first look at some ofthe complexities involved with early wooden wheels.

By the way, if you haven’t signed up to receive this weekly blog via e-mail, just type your address in the "Follow By E-mail" section above. You'll receive a confirmation e-mail that you'll need to verify before you're officially on board. Once that's done, you'll receive an email every time we update the blog. Please don't hesitate to let us know if we can be of assistance. We're looking forward to your visits each week.Please Note: As with each of our blog writings, all imagery and text is copyrighted with All Rights Reserved. The material may not be broadcast, published, rewritten, or redistributed without prior written permission from David E. Sneed, Wheels That Won The West® Archives.

By the way, if you haven’t signed up to receive this weekly blog via e-mail, just type your address in the "Follow By E-mail" section above. You'll receive a confirmation e-mail that you'll need to verify before you're officially on board. Once that's done, you'll receive an email every time we update the blog. Please don't hesitate to let us know if we can be of assistance. We're looking forward to your visits each week.Please Note: As with each of our blog writings, all imagery and text is copyrighted with All Rights Reserved. The material may not be broadcast, published, rewritten, or redistributed without prior written permission from David E. Sneed, Wheels That Won The West® Archives.