As part of that study, I’ve encountered a number ofunsubstantiated perceptions in the field; perceptions that have been repeatedenough times that they’re sometimes wrongly accepted as truth. One such experience centers on the designfunction of a wagon wheel. For instance,I’ve seen individuals shake a wheel on a wagon and if it moved side to side,declare the piece to be worn out and unsound. To be sure, wheels can wear in the hub boxings, thimble skeins, spokes,felloes, etc. Overall, though, a typicalwooden wagon wheel (non-roller bearing) is actually intended to have somelateral movement. There is a strongpurpose for that action and perhaps, it’s most appropriate to let one of themost historic and legendary wagon-making veterans explain the reason. Below is a quote from Louis Espenschied,founder of the famed Espenschied Wagon Company in St. Louis. The excerpt comes from his 1878 patent onVehicle Axle Lubricators. I’ve placedsome of the text in a bold and enlarged manner to help call out the function ofa typical wagon wheel on a thimble skein.

“This invention is animproved mode of lubricating the thimbles of wagons through the knocking actionof the wheels in their playing on the spindles; and consists in a greasereservoir or box constructed to have its opening through the hurdle or collarof the spindle, and coming flush against the hub of the wheel. The play that the wheel has longitudinally onits spindle when in motion causes its hub to knock against the collar orhurdle, thus thereby forcing the grease before it through an openingcommunicating with it, and coming out at the top of the spindle to bedistributed over the same and the box of the hub.”

It’s a bit of a wordy segment in the patent but itdoes a wonderful job in describing how the side to side action of the wheelworking in a back and forth action along the skein actually functions todistribute grease and help the vehicle run smoother.

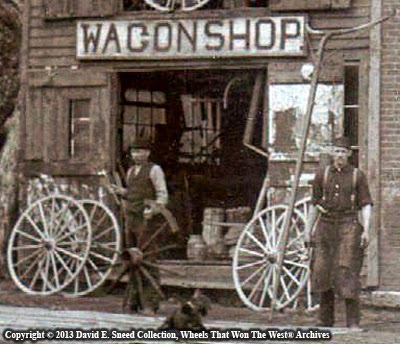

So, if some longitudinal movement is necessary, howdoes a person know how much slack is appropriate? That’s where the experience of today’sskilled wagon makers is helpful. Craftsmenlike Doug Hansen of Hansen Wheel & Wagon Shop in Letcher, South Dakota havedecades of experience and can be especially insightful with answers. In a recent conversation with Hansen, heshared that there are many factors that come into play. “Unless you’re talking about a new or unusednew-old-stock piece, there will be at least some wear on a wagon’s skeins andboxings,” said Hansen. “The wear onskeins is easier to measure since it occurs predominantly on the lower sectionswhile the boxings will wear on the full circumference. The skeins and boxings can wear bothlaterally and radially with each type requiring different evaluations andcorrective actions. If a wheel isradially out of alignment by a half inch or so, it’s going to be noticeable andcreate problems beyond the added drag to the draft. It will, ultimately, affect the soundness ofthe rest of the wheel. Wheels with aquarter inch or less of lateral and radial movement are typically still withinoriginal tolerances.” Reinforcing thatstatement as well as the quote from the Espenschied patent, the photo belowshows a period new-old-stock (never used) skein with a boxing allowing 3/16inch of lateral movement.

Our conversation with Mr. Hansen was extensive so wewill likely cover more on this subject in a later blog. Suffice it to say that from wheel-making tothe fitting of skeins on axles and a whole slew of patented wagon innovations,truly understanding these early vehicles requires a willingness to devoteoneself to documented study. Ultimately,that commitment to research and recovery of so much primary source material isa founding principle of our Wheels That Won The West® Archives. It’s a focus that not only helps to separatefact from fiction but continues to help uncover some of the rarest wheeledhistory in America.