From the challenges of smaller storage spaces and the sizes of our clothes to moving furniture through narrow door openings and even the meshing of work personalities, the topic of a right 'fit' always seems to be a part of conversations. The same issues hold true for early, horse-drawn vehicles. Each one of these machines was designed to fit and function with precision and purpose. It's a complexity that's often underappreciated and, as a result, can easily be overlooked.

In this post, I'll talk about ten places (there are more) where an incorrect fit can cause frustrations and problems. Each of these mismatched features also represents a lack of originality and, in almost every instance, the wrong-sized piece will affect the performance and, in some cases, the durability of the vehicle part or whole. With those things in mind, let's kick things off by focusing on the wagon tongue.

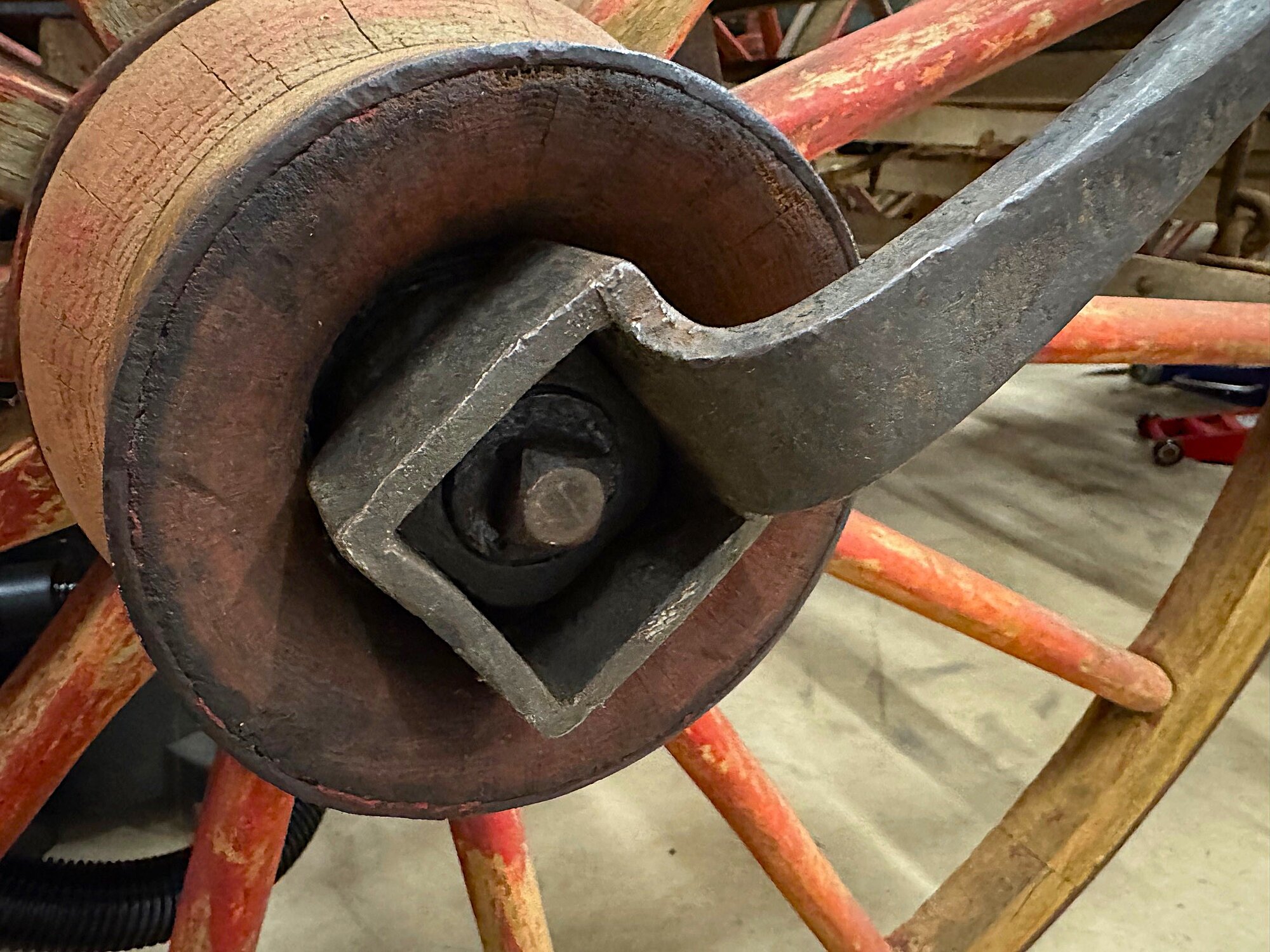

This image is for explanation purposes only as the tongue is just sitting on the bolt. However, it is clearly too small for the opening of the hounds on the wagon gear. The tongue is also too dilapidated to be of serious use. Even if the tongue were sound and solid, the fact that it is undersized for the gear would allow excessive and potentially dangerous pressures to be exerted on the Queen bolt as well as other areas.

Wagon tongues have often been broken, cut, or separated from where they were originally connected. The result can leave twenty-first century enthusiasts with the chore of finding a correct tongue for their running gear. The project of replacement is not as simple as it might seem. Not all tongues are sized the same. (Hence the presence of some universally-adjustable pieces). A correctly-fitted, wooden tongue will wedge into the front hounds, allowing the futchells and bracing to support the applied pressures. The tongue bolt (sometimes referred to as the Queen bolt) is meant to help hold the tongue in position and should not be the primary means of support for the tongue. With that said, normal wear and tear will sometimes result in the hounds weakening and allowing excess pressure to be applied to the tongue bolt. This will often cause wear marks and grooves in the bolt. This is a different situation than one where the yoke of the tongue is significantly smaller than the opening in the front hounds. When this happens, the tongue bolt is the only thing supporting all of the pressures applied to and through the tongue. If a tongue with an undersized 'Y' yoke is connected to the wagon hound opening, the tongue bolt can bend and wear with breakage possible in both wood and metal parts. It's an unsafe, unwise, and improper approach to attaching a tongue.

In the foreground of the image above is the metal reach plate for the running gear (undercarriage). Sometimes extreme pressures can cause the pin in the center of the plate to wear and deform the metal and/or wood. That degradation can also create friction that abrades and potentially weakens or binds the reach or coupling pole. Keeping a close eye on maintenance of all parts of a wagon helps ensure everything stays fully functional.

Similarly, the reach or coupling pole can be both oversized and undersized. Incorrect fits may allow excess movement or wear. Even correctly-sized reaches can have trouble fitting a slip reach if the metal of the reach plate has worn, bent, or frayed. Once again, an improper fit can result in unnecessary pressures that can compromise a vehicle's safety and proper operation. In fact, all areas of an old wagon should be continually reviewed to ensure proper working order is maintained.

Properly-sized end gates help support the box sides without adding unnecessary pressures.

Other features of a wagon that can wind up missing are the end gates. Due to different sideboard heights, box widths, and paint striping, it's not always easy to find an original match for a missing end gate. However, proper width is important as a board that's too narrow or too wide can create additional stress on the adjoining sideboards and supports.

Many folks don't realize that the skeins (metal thimbles on the ends of an axle) are sized to match the metal boxing inside the hub of a wagon wheel. Wheels with boxings that are not properly matched to the skeins can create issues that cause friction and binding within the hub. In these cases, the wagon can be harder for animals to pull and move. A wrong-sized wheel boxing can also seize up, creating safety concerns. These and other challenges make it tough to purchase a random wheel (even if the height is correct) and be assured of a correct fit.

Wagon nuts come in a range of sizes and thread patterns.

In close proximity to the wheel is the nut. I've had folks contact me looking for these threaded necessities. The problem with finding a replacement for a missing nut is that these pieces come in a number of sizes and thread patterns. Coming across the right combination is not impossible but does have the potential to feel like it.

A properly fitting wheel wrench not only makes removing a wheel easier but also minimizes the chances of the wrench slipping and causing damage or personal injuries.

While we're in the neighborhood of the wheel, let's talk about the fit of the wrench. We've covered the subject of left and right-handed threads on these nuts before but I'm not sure we've ever discussed the need for using the right-sized wrench. Located in the center of the wheel hub on a wagon, these nuts typically surround both the threaded skein on the end of the axle as well as a lag bolt in the very center of the axle end. For traditional removal of a wheel, there is no need to touch the center lag bolt. It is there to help secure the skein and should not be loosened. The larger nut holding the wheel may have excess grease surrounding the sides. If so, it's likely been there for a long period of time. It will need to be cleaned off to allow a secure fit of the wrench. If the wrench is too small, there will be no good way to apply leverage to the nut. If it's too large or the fit is compromised by dirt, grease, or some other obstruction, there is a significant chance that the wrench can slip off the nut and cause injuries. Do not second guess or downplay the importance of having a right-sized wrench. Those thoughts have a way of creating problems and, yes, that is the voice of experience you're hearing.

Next... let's say that you found the perfect running gear but need a box to match it. There are multiple sizes to running gears. In this case, the 'size' I'm referencing is the distance between the bolster standards (the uprights securing the lower box sides). The width measurement between many standards or stakes is often either 38-inches or 42-inches. However, it can also be 43-inches, 44-inches, or some other dimension. These proportions can depend on the maker, timeframe of manufacture, and even the style of box for which the running gear was built.

Our Wheels That Won The West® collection includes dozens of spring seats. Among the brands featured are... Bain, Brown, Carver, Charter Oak, Cooper, Flint, Florence, Gestring, International Harvester, Jackson, John Deere, Luedinghaus, Missouri, Mogul, Moline, Moline-Mandt, Newton, Olds, Overland, Owensboro, Peter Schuttler, Springfield, Stoughton, Studebaker, Weber, Weber & Damme, Winona, and others.

Another part that is commonly missing from old wagons is the spring seat. Because of this frequent deficiency, I've been a hunter-gatherer of seats for many years. It's not only been helpful in completing a number of my wagons but I've also been able to assist others looking to complete their own. Sometimes the springs on a seat can be moved to help the piece better fit the box. However, this can leave non-functioning holes or unnecessary hardware covering the holes.

Box rods that fit correctly help support many other parts of the wagon. Conversely, rods that are loose, short, or otherwise compromised are a recipe for regret.

Box rods can also be missing. Just as wagon boxes come in different sizes, box rods will vary in length, thread count, and overall design. In other words, there is no one-size-fits-all for box rods (the metal rods spanning the width of each end of a wagon box). Having the right rod(s) in place goes beyond the area of originality and actually helps keep the sides of the box properly supported.

Finally, when hauling these old transports, it's important to think ahead as to how the parts and whole will fit on the trailer. For instance, how will you pack the tongue, bows, spring seat, neck yoke, doubletree, single trees, and any other elements that could be or become loose? Proper storage of the pieces - where rubbing, wear, loss, or damage cannot occur - is essential.

Using an enclosed trailer to haul a period wagon can keep the antique set of wheels more secure while also helping prevent loss of parts that might rattle loose.

Ultimately, the right size, shape, strength, and care of a wagon's parts can help with better safety, security, and enjoyment of the old set of wheels. From side to side, end to end, and top to bottom, attention to every detail can be the difference in whether a part will Fit Or Fail.

Psalm 20:7