First things first... I have a correction to make in last week's blog. Incredibly, no one caught it as of this writing (or at least everyone was kind enough toturn a blind eye to my obvious oversight). Nonetheless, I clearly was in too much of a hurry and mistyped the incorporation date of the Star Wagon Company. As it's shown on the period letterhead within the blog, the correct date is 1870. So, with that out of the way, we'll move forward to this week's subject.

I recently received an email from Doug Hansen of Hansen Wheel and Wagon Shop in Letcher, South Dakota. Over the years, Doug and I have shared a mutual appreciation for the technology employed in so many aspects of early horse drawn vehicles. Truth is, there are few - if any - areas of early vehicle design that didn't have someone working on improvements. It's just one of the reasons why no two vehicles are ever the same and no period vehicle is ever just a 'simple' design. The closer you look, the more there is to see - and learn.

Doug sees a lot of America's wood-wheeled history in his shops and sometimes passes along highlights of his current projects. Not too long ago, he was working on a wheel from a Winona brand wagon. When he removed the tire, there was a groove in the top of the felloes. In most circumstances, this part of the felloe is a smooth, flat surface shaped to fit flush and tight to the bottom of the tire. In this case, while most of the top of the felloe is flat, there is the addition of an offset, cupped channel completely encircling the wheel. Some of you may remember that my December 3, 2014 blog talked about a matching tire/felloe groove technology engineered to help keep a tire on the wheel. Well, this Winona groove is designed differently but has a similar purpose.

|

| This cupped channel was designed as an oil reservoir, helping preserve the wooden felloes while keeping the tire tight. |

Knowing my enthusiasm for pointing out these special features, Doug has kindly allowed me to pass along the photo above while accompanying it with a little more info from our Archives. I should mention that this is not a feature you'll find on every Winona brand wagon nor was Winona the only well-known maker to use this.

Unlike the December 3rd blog, where a ridged bead was designed to seat inside a matching groove in the backside of the tire; this carved out, hollow channel is actually a full-circle oil reservoir meant to help preserve the wooden felloes and keep the tire tight. There were a variety of these designs in the marketplace, some being capped with a solid plug or even a screw. It's an innovation with roots at least as early as 1875 when Charles Lea of California filed for a patent on the idea.

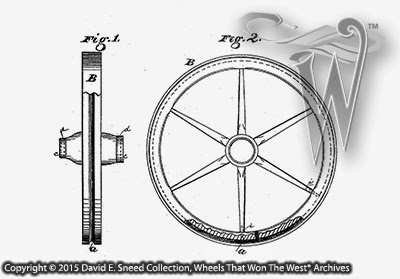

These early patent images clearly show how the cupped channel is designed to circulate oil completely around the wheel.

After Mr. Lea's patent expired, another similar design was submitted in 1898. While each concept, as well as several I've seen in practical application, was similar, they also had subtle differences. The primary purposes were to prevent undue shrinkage or swelling of the felloe while preserving the original shape and strength. The designs often allowed for spoke joints to also benefit from the oil.

Ultimately,the advancements are another great example of how these builders continually worked to enhance the quality of their products and the satisfaction of their owners. Thanks again to Doug Hansen and his team for sharing the photo. It's another reminder that things are rarely as straightforward as they appear. By the way, if you have an image you'd like to pass along or vehicle subject you'd like to see more on, drop us a line. We enjoy hearing from folks and look forward to sharing even more in 2015.